Facing Uncertainty Head-On: Lessons from the 1985 Plaza Accord

Every time you turn on the news, there’s another ominous headline about potential U.S. tariffs on Canadian goods. With so much uncertainty swirling around, it’s tempting to adopt a “wait and see” approach. But if there’s one thing history has taught us, it’s that...

Lean & Mean: Your Secret Weapon Against U.S. Tariff Challenges

If you’re a Canadian manufacturer, the mere mention of potential U.S. tariffs likely sends a chill down your spine. After all, tariffs can disrupt supply chains, inflate costs, and threaten profitability. But here’s the good news: a well-executed Lean Transformation...

Top 10 Lean Implementation Mistakes

Implementing Lean Six Sigma in manufacturing can be a powerful tool for driving efficiency, reducing waste, and improving quality. However, many companies encounter challenges that can hinder their success. Here are the top 10 mistakes to avoid when implementing Lean...

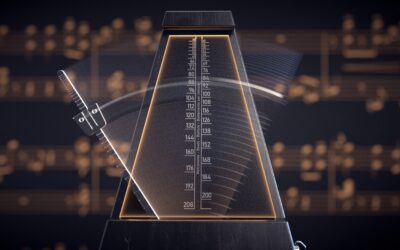

Takt Time: Lean Manufacturing’s Mysterious Metric

Takt Time: Lean Manufacturing’s Mysterious Metric In the lean manufacturing world, Takt Time is frequently misunderstood, and often mistaken for its dance partner, Cycle Time. So what exactly is Takt Time, how do you use it, and how it is distinct from Process Cycle...

Brewing Efficiency: Embracing Lean Manufacturing in the Craft Beer Industry

In the world of craft beer, lean manufacturing might seem like an unexpected guest in the taproom. However, the opportunity for breweries to embrace lean principles is a game-changer that can revolutionize operations, enhance quality, and pour a glass of efficiency....

Goldilocks, the Three Bears and Just Right Inventory Levels

In the story of Goldilocks and the Three Bears, Goldilocks sought perfection—a bed, a chair, and porridge that were "just right." This analogy mirrors the quest for the "just right" inventory balance in the context of Lean transformation in a manufacturing plant....

Unlocking Potential: Distinguishing the 6 Big Losses in Manufacturing Operations

For manufacturing operations, recognizing and addressing inefficiencies is the key to unlocking the full potential of a business. The concept of the 6 Big Losses offers a strategic framework for identifying and mitigating common challenges that impede operational...

10 Common Problems Faced by Manufacturing Operations

For manufacturing operations the journey towards operational excellence is often marked by a series of challenges. Understanding and addressing these challenges is pivotal for organizations aiming to thrive in the dynamic world of manufacturing. In this blog post,...

Everything You Need to Know about Yield Optimization

In Lean Manufacturing, optimizing efficiency and minimizing waste are the focus. One powerful tool that plays a pivotal role in achieving these goals is Yield Analysis. In this blog post, we’ll look at how to perform Yield Analysis, exploring its significance,...

Quality Metrics to Empower Your Success

In Lean Manufacturing, the pursuit of operational excellence extends beyond efficiency and waste reduction to include quality. To measure and improve quality performance, Lean Practitioners rely on key metrics such as First Time Right (FTR), Throughput Yield (TPY),...