Chaos Racing

Lean Simulation

Discover the Power of Lean through Play!

There are seemingly endless applications of Lean Six Sigma concepts and tools in business, but it can be hard to figure out where to start. There are countless books, courses and materials available online, so what’s the best way to introduce a group of people to Lean Six Sigma? At Engineering Possibilities, we say the best way to start your Lean Six Sigma journey is to discover the power of lean through play!

Globally, children spend over 5 billion hours each year playing with Lego bricks. So why does the fun have to stop when we grow up?

Introducing Chaos Racing!

Chaos Racing is a fictional race car manufacturing company with dreams of leading the Lego Race Car industry with their novel car design which is lighter and faster than conventional Lego race cars. While the company admits they are experiencing some production and quality problems, they have confidence in their race car design and are committed to work harder in order to deliver orders to their customers on time!

In the Lean Simulation exercise, your team members will play the role of Chaos Racing employees, working in jobs ranging from Automotive Technicians to Forklift Operators and Quality Control. In the first round of play, the extent of Chaos Racing’s operational problems quickly becomes obvious – nothing works! There are broken processes, poor work instructions and extreme bottlenecks. If these problems don’t get corrected soon, Chaos Racing is headed for bankruptcy.

Participants are given instructions to build 30 race cars during their 20 minute shift. Chaos erupts as teams struggle to build just a few on-spec race cars during the shift, falling significantly short of customer demand. At the end of the shift, their performance is reviewed and analyzed, examining process metrics for production, quality and cost. It doesn’t paint a pretty picture – something has got to change!

Enter: Lean Six Sigma! Before their second shift begins, participants learn the basic concepts of Lean Six Sigma. They discover core lean concepts including optimizing process flow, workload balancing and eliminating waste. Participants then spend 20 minutes leading their own Lean Kaizen Event to improve the Chaos Racing production process ahead of Round 2.

The team’s second shift at Chaos Racing undoubtedly goes better than their first! There is some semblance of organization and flow emerging. It’s not perfect, but definitely better! Teams typically increase the race car production rate significantly with some even matching customer demand. A few telltale remnants from the past shift still linger in Round 2 so after more lean training on workplace organization, quick changeover, lean material flow and cell design, a second Lean Kaizen Event is facilitated by the participants to elevate performance.

By the end of Round 3, many teams are able to produce all 30 race cars in under 5 minutes. A remarkable achievement that leaves the participants at the source of transforming the process and hungry to apply their discoveries to their real jobs!

Unleash the Power of Lean in Your Business

This program is designed for successful and growing businesses operating in any sector, providing any service or manufacturing any product and most importantly, are interested in empowering your employees to succeed. You might have an emerging interest in Lean Six Sigma and you’re not quite sure where to begin. The Chaos Racing Lean Simulation is a great starting point to establish the foundation for unleashing the power of Lean in your operations. You’re clear you have process problems and you’re looking for clarity, direction and peace of mind in your business. When you work with Engineering Possibilities, you’ll increase the efficiency and effectiveness of your business, increase productivity, eliminate waste and realize significant cost savings!

Lean Six Sigma Made Simple

The name alone just sounds complicated. The truth is, Lean Six Sigma is simpler than you think! Lean Six Sigma is a set of tools that create streamlined and highly effective processes that reflect the heart and soul of your business and the difference you’re out to make. Housed in the context of improving Chaos Racing’s operations, you’ll discover the power and simplicity of Lean and see opportunities to apply Lean Six Sigma in your own business.

Lean is about streamlining processes and eliminating waste. Six Sigma is about reducing variation in processes. Together Lean Six Sigma works to increase the efficiency, effectiveness and the overall quality of your business processes. With my expert guidance, you won’t go wrong.

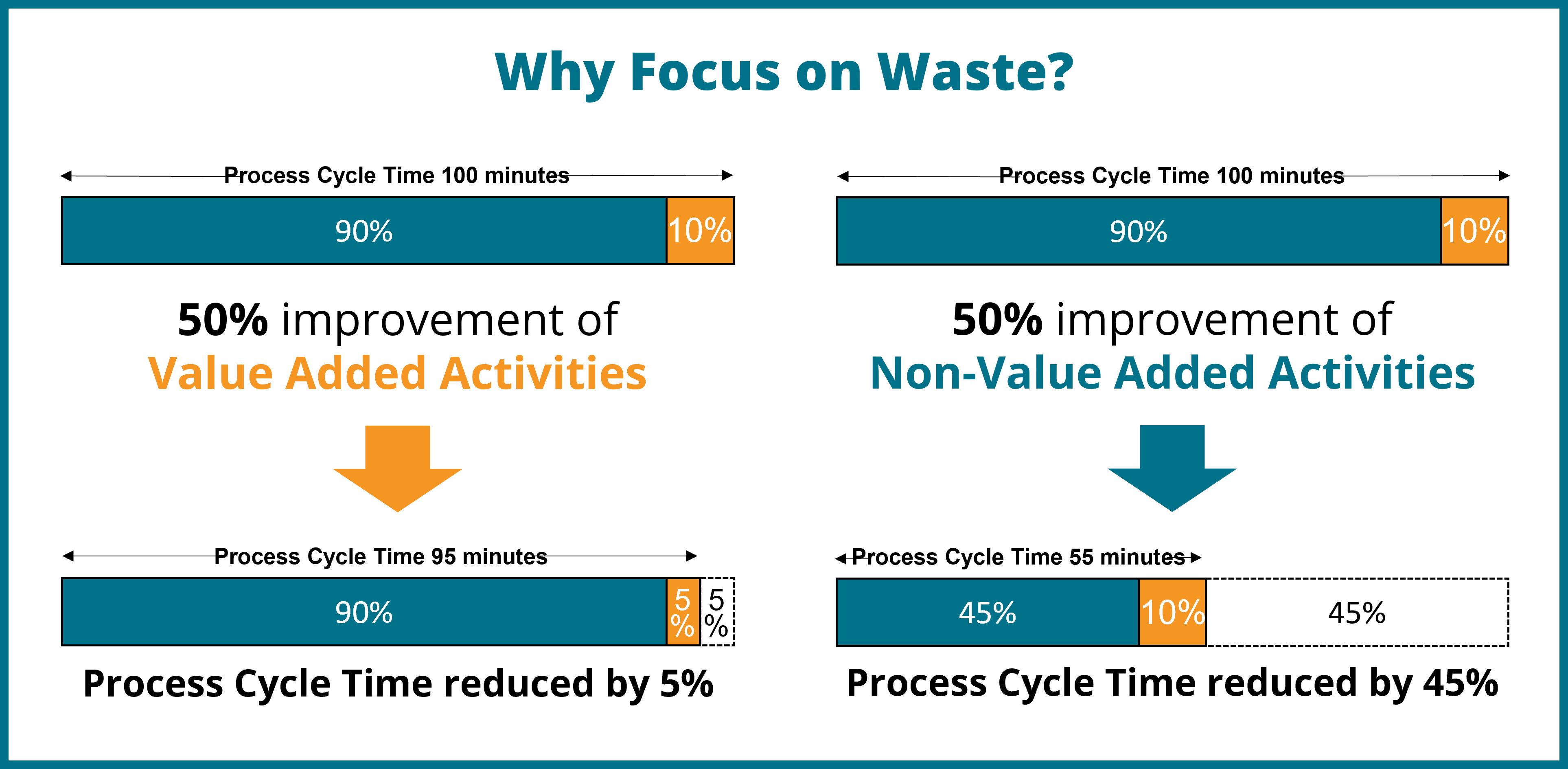

What You Don’t Know is that Business Processes Typically Contain up to 90% Waste

Process Wastes are the activities that consume time, money and resources and don’t add value to your customers – we call these Non-Value Added Activities. These activities are the source of your headaches and frustrations: your process breakdowns, errors and delays. The problem is that we don’t often get to the source of our process problems. Instead we get busy trying to manage and address all the symptoms of our problems by adding more time, money and resources. We’ll add inspection processes to deal with product quality issues, increase inventory levels to avoid shortages, increase production speed to make more product (think: the I Love Lucy chocolate factory). All of these “band-aid solutions” cost money and increase your operating costs, adding to the illusion that the answer to being successful in your business is being able to do more.

What do Lego Race Cars have to do with my Business?

Not much, unless your business happens to build race cars. The simulation isn’t really about building race cars. The simulation is about identifying business processes that don’t work as well as they could. Last I checked, every business has some of those!

The Chaos Racing Lean Simulation is about empowering people to identify and make improvements to a process to achieve a common goal. It begins in a space of chaos and ends with an efficient and effective production process, all created by the participants.

Program Details

The Chaos Racing Lean Simulation Training makes learning about lean fun! Whether it’s a memorable afternoon team building session or a 1 day intensive session to kickstart the lean transformation of your business, your team won’t forget their experience and will eagerly apply their lean discoveries to the daily work.

The minimum number of participants required to run the simulation is 8 people. With 17 or more participants, you can host a double sim with a healthy dose of competition!

Customized training programs are available. Book a complimentary 30 minute Discovery Call to get started and bring Chaos Racing to your organization!

Do It Yourself! Sim Kits Now for Sale with Facilitator Training

Bring the power of lean to your organization with your own Chaos Racing Simulation Kits complete with Facilitator Training.

Chaos Racing Simulation Kits, $1,095 CAD per Kit

Everything you need to introduce your organization to the power of Lean:

- Over 1,200 Lego Bricks

- Laminated Work Instructions

- Forklift Buckets

- Carrying Case

- Tent Cards

- Warehouse Baskets

- Simulation PowerPoint Slide Deck

- Simulation Results Excel Spreadsheet

- Electronic Facilitator Guide, Setup Checklists and Worksheets

Chaos Racing Facilitator Training Program, $625 CAD per person

Train your staff to lead the Chaos Racing Lean Simulation:

-

- Electronic Facilitator Guide and Checklists

- 1.5 Hour Recorded Training Session delivered over Zoom

- Unlimited Follow Up Support via Email or Zoom

Client Testimonials

“What an eye-opening experience of amazing value! The first round of the simulation was similar my own work experiences with the level of frustration that I experienced. It was so empowering to get to redesign and improve the manufacturing process to achieve efficiency and flow, I saw many connections to my real job where I could apply what I learned in this powerful program!”

“That was too close to real life – too close!!”

“The most fun I’ve ever had at work!”

Frequently Asked Questions

What do I know about your business/industry?

Potentially nothing and that’s okay! You know your business and I know processes. Together we will create the foundation for your continued success and business growth. After working in the chemical processing industry for 9 years I made the leap to healthcare, an industry I literally knew nothing about. The “medical speak” the doctors and nurses on my project teams engaged in was well over my head, yet the processes they were trying to work with and create were my expertise. Working together, we designed and created processes that enabled their medical procedures and elevated the patient experience. I’m still in the dark about most things medical, but that didn’t stop me from leading several highly successful projects in the medical field.

How does Lean Six Sigma apply to my business? Isn’t it only for large corporations?

Lean Six Sigma sounds really complicated, is it too technical for me?

You’re right, Lean Six Sigma does sound really complicated but don’t worry, that’s where I come in. During the Lean Simulation workshop, you’ll discover the simple and practical nature of lean as it applies to both the LEGO airplane process and your own work processes. I promise it’s simpler than it sounds!

What is the payment structure for the Chaos Racing Lean Simulation Training?

Full Payment for the Chaos Racing Lean Simulation Training is due when you book your training workshops.

Why Work with Engineering Possibilities?

I’m Holly Blair, I’m a Lean Consultant and the founder of Engineering Possibilities.

I’m a Chemical Engineer with over 17 years of experience in chemical processing, healthcare, service and manufacturing industries.

As a Certified Lean Six Sigma Master Black Belt, Change Management Practitioner and Certified Executive Coach, I provide an innovative approach to process improvement by integrating Systems Thinking with Lean Methodologies. I am an engaging facilitator of Lean Training Workshops and Kaizen Events that leave my Clients empowered with the capability to create lean process improvement results in your own environments. I have a knack for distilling your processes down to what really works, creating ease and simplicity in otherwise chaotic and complex environments.

Bring your Favourite Childhood Toy to Work!

Make Learning about Lean Fun!

- Host a memorable team building event that leaves your employees empowered and energized

- Establish the foundation for the Lean Transformation of your Business

- Expose your Team to new ways of thinking and dealing with process problems

- Develop a new ability to recognize process waste

- Create actions to reduce and eliminate waste