In Lean Manufacturing, the pursuit of operational excellence extends beyond efficiency and waste reduction to include quality. To measure and improve quality performance, Lean Practitioners rely on key metrics such as First Time Right (FTR), Throughput Yield (TPY), and Rolled Throughput Yield (RTY). In this blog post, we will examine the application, benefits, and challenges of implementing these important Lean quality metrics.

- First Time Right (FTR): The Benchmark for Quality Precision

First Time Right, as the name suggests, measures the percentage of products or processes that meet quality standards without the need for rework or correction. It serves as a benchmark for the initial quality of output. The benefits of using the First Time Right quality metric include:

Reduced Rework Costs: FTR minimizes the need for corrections and rework, leading to significant cost savings associated with labor, materials, and time.

Enhanced Customer Satisfaction: Consistently delivering products right the first time enhances customer satisfaction, fostering loyalty and positive brand perception.

Streamlined Processes: FTR encourages a culture of precision and attention to detail, streamlining production processes for greater efficiency.

Two challenges associated with the First Time Right quality metrics are difficulties identifying root causes of quality problems and the requirement for employees to be trained and well-versed in quality concepts.

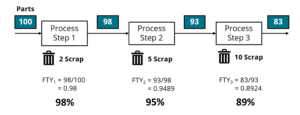

In a manufacturing plant, 100 parts go into the first process step, 2 are scrapped, and 98 defect-free parts go to the next stage. 98 parts enter the second process step, 5 are scrapped, and 93 defect-free parts go to the next step. 93 parts go into the third process step, 10 are scrapped and 83 defect-free parts leave the process. The First Time Right quality for step 1 is 98%, 95% for step 2 and 89% for step 3. The First Time Right quality for the overall process is 83 defect-free parts divided by 100 parts that entered the process for a value of 83%.

- Throughput Yield (TPY): Unveiling Overall Process Effectiveness

Throughput Yield measures the effectiveness of an entire process by assessing the percentage of defect-free units that pass through each stage of production. It accounts for scrap product and re-worked products to provide insight into the cumulative impact of multiple process steps on overall quality. The benefits of applying Throughput Yield quality metrics include:

Process Visibility: TPY offers a holistic view of process effectiveness, allowing organizations to identify bottlenecks and areas for improvement.

Strategic Decision Making: By understanding the impact of each process step on quality, organizations can make informed decisions to optimize the entire production flow.

Enhanced Resource Utilization: Improving TPY often involves optimizing resource utilization, leading to cost savings and increased productivity.

In organizations with complex multistage processes, calculating and managing Throughput Yield can be complicated. Clear process mapping and data collection are vital. Additionally, organizations may face challenges in maintaining a balance between speed and quality, especially in high-speed production environments.

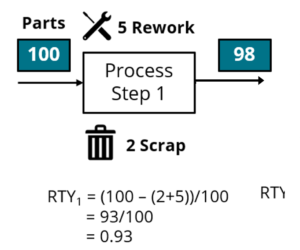

In a manufacturing plant, 100 parts go into the first process step, 2 are scrapped, 5 are reworked and 98 defect-free parts go to the next stage. The Throughput Yield is 100 parts minus 2 scrap parts minus 5 re-worked parts, divided by the 100 original parts, for a value of 93%.

- Rolled Throughput Yield (RTY): Ensuring End-to-End Quality Consistency

Rolled Throughput Yield extends the concept of Throughput Yield by assessing the overall quality of a product or process through multiple stages, providing a comprehensive picture of end-to-end quality consistency. Rolled Throughput Yield accounts for the scrap product and re-worked parts at each production stage and calculates an overall yield percentage for the process.

End-to-End Quality: RTY ensures that quality is maintained consistently across all stages, minimizing the risk of defects in the final product.

Optimized Process Flow: Identifying and addressing issues at each stage of the process optimizes the overall flow, enhancing efficiency and minimizing waste.

Continuous Improvement Focus: RTY encourages a continuous improvement mindset, as organizations strive to improve quality at every stage of the production process.

Calculating Rolled Throughput Yield requires accurate data collection at each stage, as any inaccuracies can lead to misinterpretation of overall quality performance. Additionally this comprehensive quality metric drives the need for process improvements across multiple stages which requires coordination and integration, presenting a challenge in organizations with siloed departments.

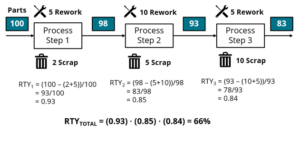

In a manufacturing plant, 100 parts go into the first process step, 2 are scrapped, 5 are reworked and 98 defect-free parts go to the next stage. 98 parts enter the second process step, 5 are scrapped, 10 are reworked and 93 defect-free parts go to the next step. 93 parts go into the third process step, 10 are scrapped, 5 are reworked and 83 defect-free parts leave the process. The Throughput Yield for process step 1 is 93%, step 2 is 85%, and step 3 is 84%. The Rolled Throughput Yield is the product of the Throughput Yield for all process steps, which works out to 66% in this example.

In the quest for Lean excellence, quality metrics assess your progress towards precision and consistency. First Time Right, Throughput Yield, and Rolled Throughput Yield illuminate the path to heightened quality performance. Embracing these metrics not only enhances product quality but also instills a culture of continuous improvement, positioning organizations for sustained success.

Recent Comments