Transform your Manufacturing Operations

Struggling with Operational Chaos?

Small and mid-size manufacturing operations face several operational challenges that can impede growth, hinder efficiency, and drain resources. It can feel like a losing battle with the experience of never quite getting ahead before the next problem arises. You’re constantly dealing with:

-

- Rising costs for raw materials, utilities, and labour that strain your budget and reduce profitability.

- Rising costs for raw materials, utilities, and labour that strain your budget and reduce profitability.

-

- Quality problems including high defect rates, unnecessary re-work activities, excessive scrap material, and recurring issues that threaten your revenue and your reputation.

-

- Inefficient workflows that hinder productivity, lengthy changeovers that slow down production, and process bottlenecks and reliability issues that impede the flow of your operations.

-

- The dilemma of managing inventory levels to avoid both excessive inventory and stockouts, both of which can disrupt operations, delay deliveries, and reduce profitability.

-

- Workforce issues such as low morale, insufficient training, and ineffective communication that undermine employee engagement and hinder performance.

-

- The misconception that Lean only works for larger corporations creates skepticism and a reluctance to adopt efficient practices.

With the right approach tailored for your organization and the power of Lean solutions, these challenges can be turned into stepping stones towards success.

Creating New Possibilities

Imagine stepping onto the shop floor of your manufacturing facility after you’ve undergone a Lean Transformation. There is a buzz of energy

and purpose, as your once chaotic operations now run with efficiency and precision.

Reduced Costs: You no longer fear conversations about the profitability of the business as you’ve found the correct dials and levers to effectively manage your costs. You’ve achieved significant cost savings through the elimination of process waste and inefficiencies, balanced workloads, and streamlined your processes to maximize quality production.

Streamlined Workflows: As you walk through the production area, you notice a dramatic change in the flow of work. Gone are the days of haphazard movement and cluttered workstations. Instead, you witness a seamless choreography of tasks, executed with precision to minimize waste and maximize productivity. With streamlined workflows now in place, you can confidently meet customer demand with ease.

Efficient Processes: Streamlining your processes for efficiency results in enhanced productivity, shorter lead times, and increased throughput, faster order fulfillment, higher customer satisfaction, and lower operating costs.

Optimized Inventory Levels: Having the right amount of materials on hand ensures just-in-time supply, allowing you to operate with reduced carrying costs while minimizing the risk of overstock and stockouts. Establishing the right inventory levels has allowed you to optimize cash flow, free up valuable warehouse space, and ensure that resources are allocated efficiently.

Improved Quality: High quality is now the standard for your operations, achieved by implementing standard work, error prevention and streamlined processes. Your commitment to quality enhances customer satisfaction and loyalty and drives operational efficiency, reduces costs, and positions your business for long-term success.

Engaged Workforce: Your team is empowered through their involvement in improvement initiatives and Lean training, leading to increased morale, loyalty, and productivity.

Harnessing the Power of Lean: Embracing Lean principles has allowed your organization to develop a sense of innovation, agility, and adaptability, enabling you to thrive as a small manufacturer in a competitive market.

Customized Strategies, Proven Results

Explore Our Lean Consulting Services

Lean tools and solutions tailored to the needs of your operation form the cornerstone of our approach to consulting. From standard work and error prevention to value stream mapping and continuous improvement, we leverage the power of Lean methodologies to drive sustainable change and foster a culture of excellence within your organization. By eliminating waste, optimizing processes, and empowering your workforce, we enable you to achieve levels of efficiency, quality, and profitability you never thought possible.

Lean Transformation

Maximize business performance with our customized Lean Transformation program including Kaizen Events and Lean Training.

Kaizen Workshops

Accelerate your lean transformation with our focused, rapid improvement events that make a real impact on your bottom line.

Process Mapping

Map your processes to identify and eliminate waste, elevate process efficiency, improve quality and remove production bottlenecks.

SMED Quick Changeovers

Faster equipment setups and changeovers equals more revenue, not to mention reduced costs, more flexibility and higher quality.

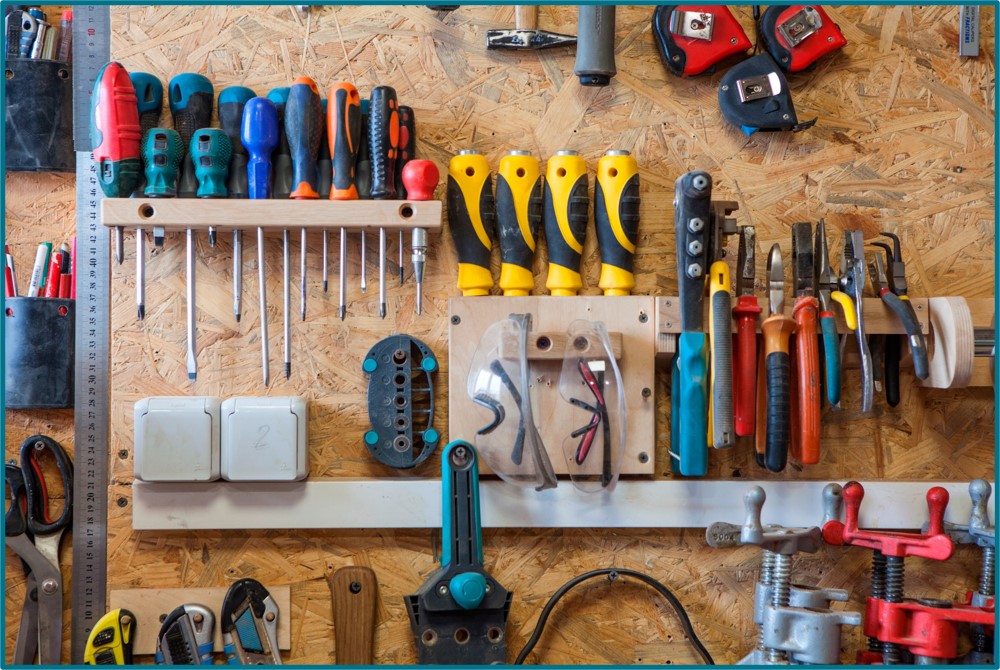

5S Implementation

Stop searching for tools and materials. Organize your workspaces with the foundational first step of your Lean Transformation.

Process Optimization

Increase productivity, reduce waste, slash process cycle time, increase throughput and be more efficient with fundamentals Lean tools.

Lean Factory Layout

Maximize efficiency and reduce motion and transportation waste with a lean factory layout for your new or expanded production plant.

Visual Management

Identify and correct process issues in real time and with simple, relevant metrics that easily communicate the status of your operations.

Daily Lean Leadership System

Implement a Management Operating System to elevate performance and drive accountability with Lean tools and structured meetings.

Expected Results

We promise to deliver tangible, measurable results for your business. From reducing costs and improving quality to streamlining processes and enhancing efficiency, our tailored Lean consulting solutions are designed to drive real, sustainable change that positively impacts your bottom line.

-

- Improve process performance, availability, and quality by 20% or more

- 10% to 40% reduction in process waste and operating costs

- Eliminate 80% to 100% of your re-work activities

- Improve process performance, availability, and quality by 20% or more

Who is Holly?

I’m a Chemical Engineer and Lean Six Sigma Master Black Belt with over 17 years of experience in chemical processing, healthcare and manufacturing industries.

I started my career as a process engineer and worked in the chemical processing industry for nearly 10 years. Along the way, I discovered the power of Lean Six Sigma to transform organizations and make a massive difference for the people who work there. I’m a Lean Six Sigma Master Black Belt, Professional Engineer, Change Management Professional and a Certified Executive Coach. I have a knack for distilling business processes down to what really works, creating ease and simplicity in otherwise chaotic and complex environments.

I created Engineering Possibilities to make a difference for small to mid-size manufacturing operations and fast growing entrepreneurial endeavors with Process Transformation.

What’s different about Engineering Possibilities?

I won’t tell you what’s wrong, what to do, or how to do it. I meet you where you are and co-create a lean future to be fulfilled in our partnership. My focus is on empowering the people in your organization and delivering business results. I am that your people are your best resource and believe that there are no inherently bad people, there are good people trapped in bad processes. I’m here to make a real difference for the people in your organization and your bottom line.

Ready to Transform your Operations?

Don’t let operational challenges hold you back from achieving your full potential. When you partner with Engineering Possibilities, you have the support and expertise you need to overcome obstacles, seize opportunities, and take your business to new heights. Whether you’re struggling with rising costs, quality issues, inefficient processes, or unmotivated workforce, we have the solutions you need to succeed.