Black Belt Training & Certification

Upgrade your Process Improvement Skills to Ninja Level!

24 Week Live Virtual Lean Six Sigma Black Belt Certification

Unleash the power of lean in your organization and supercharge your career!

Get Ahead of the Curve with the Power of Lean Six Sigma

Learn how to create simple, effective and efficient processes that transform your organization

Imagine being able to:

- Be more effective without getting busier

- Deliver your product or service to your customers in any circumstances

- Empower your employees to continuously improve the business

- Significantly and sustainably reduce your operating costs

- Expand your business without impacting productivity

- Solve those pesky, chronic, systemic issues in your operations

- Reduce defects, accelerate process cycle time and increase quality, all at the same time

Lean Six Sigma Black Belt Certification

This program is designed for Operations Leaders, Business Owners, Engineers, Managers, Quality Professionals, Entrepreneurs, Emerging Leaders and Business Analysts who want to supercharge your business performance and advance your career.

Whether you’re an entrepreneur building a business, a manufacturing operation or an established service provider, the Lean Six Sigma Black Belt Certification Program will develop your capacity to lead impactful and sustainable lean process improvement initiatives. You will develop an expertise in lean processes with a powerful set of tools to improve production systems, elevate service delivery, eliminate defects and guarantee quality.

Program Outcomes

By the end of the 24 week virtual training program, participants are enabled to:

- Employ lean tools to balance workloads, eliminate bottlenecks, increase efficiency and accelerate process changeovers resulting in increased productivity and higher quality throughput at a reduced cost

- Monitor process performance using lean statistical tools

- Identify improvement opportunities and develop detailed execution plans for improvement initiatives

- Trace operational problems back to their root causes and design effective solutions

- Optimize value streams by shortening process cycle time, improving quality and enabling continuous production flow

- Be a leader in your organization with the capacity to implement effective change

Do I really have time for this?

You’re busy – I get it.

This program is designed for busy professionals who want to make a difference for your organization. You’ll complete a Black Belt Project that leverages the skills you learn, making a direct impact on the performance of your business by delivering at least $50,000 of value to your organization. The weekly sessions are recorded so you can review them later or catch up on content you’ve missed.

This program is designed for big people who are up to big things – we won’t waste your time.

The Black Belt Certification program allowed me to streamline my business and become much more efficient! I now have the tools to create my own processes so I can expand my business and work with more clients than I ever could before! Totally worth the investment.

This program has been extremely valuable for me as a leader at Cask, and for my personal development. I learned a set of lean tools and techniques that allowed me to build a full cost saving analysis of the Install and Commissioning portion of the business. Thanks to this course I have actionable plans to save the business thousands of dollars and implement a more efficient way to get our equipment running successfully in the field!

Your Investment

The cost of the Lean Six Sigma Black Belt Certification Program $6,495 CAD per participant.

The program is eligible for provincial training grants, covering 67% to 83% of your training cost depending on your location.

Space is limited, register early to ensure your spot!

How it works

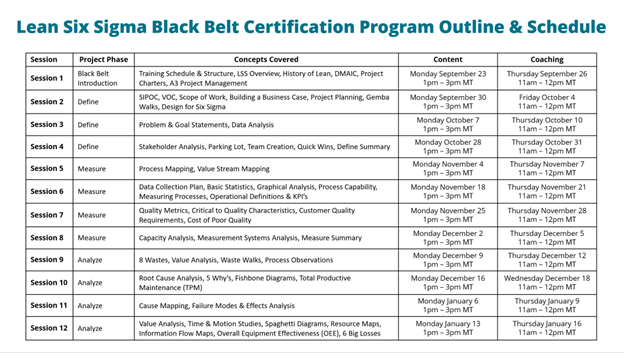

The program is delivered live on Zoom in a series of 6 modules over 24 weeks. Two hour weekly training sessions are held on Mondays from 1pm to 3pm MT with one hour follow up coaching sessions on Thursdays from 11am to 12pm MT. All sessions are recorded and are available to participants on the course website.

Fall 2024 Black Belt Certification starts Monday September 23rd

What’s Included in the 24 Week Black Belt Certification Program:

- 48 hours of instruction delivered in 2-hour sessions per week

- 24 hours of group coaching delivered in 1-hour sessions per week

- Four 1:1 Private Coaching sessions throughout the program

- Unlimited email support from your Master Black Belt Instructor

- Black Belt Project delivering a minimum value of $50,000 to your organization

- Private course website access with all course resources and session recordings

- Additional Coaching after the program for successful project completion

- Free Ultimate Lean Toolkit with over 30 downloadable lean tools and templates

- Black Belt Certification Exam (100 questions, open book, 80% passing grade)

- Electronic Lean Six Sigma Black Belt Certificate upon successful completion of the program

Lean Six Sigma Black Belt Program Overview

Module 1 - Introduction to Lean Six Sigma & Black Belt Project

Discover the world of Lean Six Sigma and what’s posible for your organization

Learn the history of lean and get introduced to the DMAIC project framework. Define the scope and intention of your Black Belt Project and create your Project Charter. You’ll apply everything you learn in the program to your project and make a real impact in your organization.

Module 2 - Define

Set the intention for your process improvement efforts

Define the scope of your improvement project, create a high level map of the process and learn basic statistics to define your problem and goal statements. Learn to listen to the voice of your customer and go see the process in action on a Gemba Walk. Engage your project team members and launch your Black Belt project.

Lean Six Sigma Tools: SIPOC Diagrams, Voice of the Customer, Gemba Walks, Problem & Goal Statements, Stakeholder Analysis, Project Scoping, Project Charters, A3 Project Management

Module 3 - Measure

Capture the Current State of your process

Build a Swimlane process map, collect data to measure your process and identify Quick Wins to execute. Build your data collection plan, learn basic statistics and graphical analysis techniques, assess your process capability and define quality metrics. Create Operational Definitions and set project KPI’s to establish the baseline for your improvement efforts.

Lean Six Sigma Tools: Data Collection Plans, Basic Statistics, Graphical Analysis, Process Capability, Operational Definitions, Measurement Systems, Quality Metrics, Quick WIns, Process Mapping, Value Stream Mapping

Module 4 - Analyze

Get to the source of your problems

Identify the 8 Wastes in your process and complete a Value Analysis to identify improvement opportunities. Perform Root Cause Analysis to solve operational issues and conduct process observations to determine appropriate improvement actions. Ensure you identify the root causes of problems before designing solutions.

Lean Six Sigma Tools: 8 Wastes, Value Analysis, Waste Walks, Root Cause Analysis including The 5 Why’s, Fishbone Diagrams, Cause Mapping, Failure Modes & Effects Analysis, Statistical Data Analysis

Module 5 - Improve

Design and implement lean solutions

Discover powerful lean process improvement tools to streamline processes, eliminate waste and increase productivity and quality. Apply lean tools in your project and realize significant savings and process improvements. Develop effective implementation plans and pilot solutions to achieve the best possible outcomes. Learn project management skills to execute improvements that make an impact.

Lean Six Sigma Tools: Creating the Future State, The Merlin Method, Poka-Yoke, Kanban, Lean Material Flow, SMED Quick Changeovers, 5S Workplace Organization, Cell Design, Workload Balancing, Pull Systems, Cyle Time, Takt Time, Improvement Idea Brainstorming and Prioritization, Implementaion Plans, PDCA Cycles and Pilots, Action Registers and Project Management Tools

Module 6 - Control

Sustain the Gains

Develop powerful process sustainment plans to ensure the long-term success of your improvement actions.

Lean Six Sigma Tools: Process Sustainment, Standard Work, Visual Management, Daily Lean Leadership Systems, Process Monitoring and Dashboards, Control Plans, Change Management, Process Documentation, Communication Plans, Training Plans

Your Lean Instructor

Hi! I’m Holly Blair and

I’m a Lean Consultant.

I’m also a Chemical Engineer and Lean Six Sigma Master Black Belt with over 17 years of experience in chemical processing, healthcare and manufacturing industries.

I started my career as a process engineer and worked in the chemical processing industry for nearly 10 years. Along the way, I discovered the power of Lean Six Sigma to transform organizations and make a massive difference for the people who work there. I’m a Lean Six Sigma Master Black Belt, Professional Engineer, Change Management Professional and a Certified Executive Coach. I have a knack for distilling business processes down to what really works, creating ease and simplicity in otherwise chaotic and complex environments. Engineering Possibilities was born in 2018 to make a difference for small to mid-size manufacturing operations and fast-growing entrepreneurial endeavors with Process Transformation. I’m excited to share my passion for process improvement with you in this program!

Black Belt Certification Process

Apply

Submit your program application and complete your Consultation Call

Participate

Participate in the 24 week live virtual training sessions

Get Certified

Complete your Black Belt Project and pass the Black Belt Certification Exam

Have Questions?

Schedule a complimentary 30-minute conversation to discuss how

Black Belt Certification can make the difference for your company and your career.