Takt Time: Lean Manufacturing’s Mysterious Metric

In the lean manufacturing world, Takt Time is frequently misunderstood, and often mistaken for its dance partner, Cycle Time. So what exactly is Takt Time, how do you use it, and how it is distinct from Process Cycle Time?

Distinguishing Takt Time

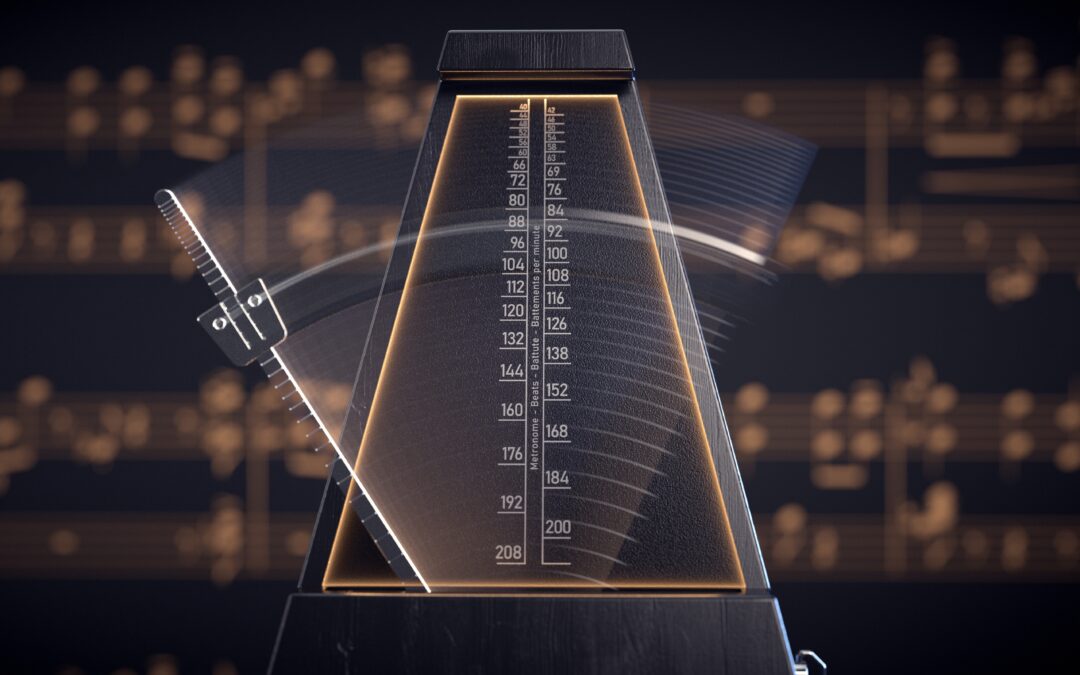

Takt Time, derived from the German word “takt,” meaning the beat or rhythm, is the heartbeat of lean manufacturing. It measures the cadence or rate at which a product must be produced to meet customer demand. Calculated by dividing the available production time by the customer demand, Takt Time prevents overproduction, aligns production with customer demand, and provides a target to optimize resources.

Yet, Takt Time is commonly misunderstood. Many people see it solely as a mathematical formula and overlook its transformative power as a strategic tool. Takt Time isn’t merely a number you calculate; it’s a philosophy that guides manufacturing processes toward alignment with customer demand, creating a culture of continuous improvement.

Takt Time’s Dance Partner: Process Cycle Time

While Takt Time dictates the overall rhythm of the manufacturing process, Cycle Time focuses on the duration of individual steps within the process. These two metrics work together to optimize efficiency on the shop floor.

Takt Time governs the overall pace of production, aligning it with customer demand. Takt Time is directly linked to Customer Demand and works to ensure production rates match customer demand rates. Using Takt Time creates a mindset of continuous improvement by aligning production with customer demand.

Cycle Time applies to specific tasks and processes and measures the time it takes to complete each step. The efficiency of individual processes within the production flow are analyzed and specific opportunities for process improvement are identified to maximize process efficiency and minimize cycle time.

Demystifying Takt Time: A Strategic Tool for Efficiency

Takt Time isn’t a mere calculation; it’s a strategy that transforms manufacturing operations. Its influence extends beyond the shop floor, guiding teams to synchronize with customer demand and eliminate waste. As lean manufacturing continues to evolve, a deeper understanding of Takt Time as a strategic, culture-shaping metric is essential for companies striving for operational excellence.

Takt Time, although often misunderstood, is a beacon of efficiency in lean manufacturing. When paired with its dance partner, Cycle Time, these metrics create a dynamic duo that optimizes the manufacturing dance, ensuring each step is in harmony with market demands. Organizations keen to elevate their efficiency and cost effectiveness can use Takt Time, and recognize it not just as a formula but as a guiding philosophy that propels businesses toward efficiency, customer satisfaction, and continuous improvement.

Recent Comments