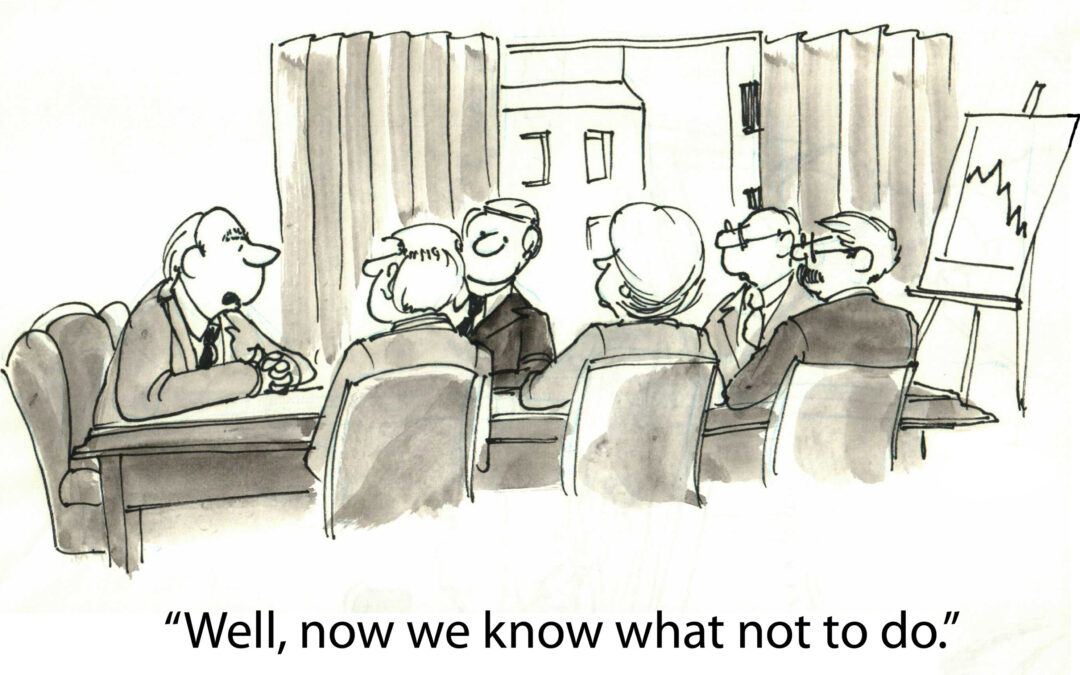

Implementing Lean Six Sigma in manufacturing can be a powerful tool for driving efficiency, reducing waste, and improving quality. However, many companies encounter challenges that can hinder their success. Here are the top 10 mistakes to avoid when implementing Lean Six Sigma in your operations:

- Lack of Clear Objectives: Starting without clear, measurable objectives can lead to confusion and lack of direction. Define specific goals tied to business outcomes from the start and create a clear picture of the future you are out to create through Lean Transformation.

- Choosing the Wrong Projects: Selecting projects based on intuition rather than data-driven analysis can result in tackling issues that don’t yield significant improvements. Projects should be prioritized based on their potential impact on key metrics.

- Not Tailoring to Organizational Needs: Applying a one-size-fits-all approach without considering the unique needs and challenges of your organization can lead to ineffective solutions. Customize Lean Six Sigma initiatives to fit your company’s culture and processes.

- Ignoring Process Variation: Neglecting to address process variation and instability can undermine your improvement efforts. Ensure processes are stable and capable before implementing Lean Six Sigma tools. Hint: Don’t skip the Measure phase!

- Relying Solely on Tools: Lean Six Sigma is more than just a toolkit. It’s a philosophy that requires a deep understanding of customer needs, continuous improvement, and cultural change. Focus on lean principles and philosophy over tools.

- Misinterpreting Data: Incorrectly interpreting data or using insufficient data can lead to misguided decisions. Invest in robust data collection and analysis methods to ensure accurate insights and informed decision-making.

- Lack of Leadership Support: Without visible support and active involvement from leadership, lean initiatives struggle to gain traction or sustain momentum. To be successful, leaders need to champion Lean Six Sigma and allocate resources accordingly.

- Ignoring Resistance to Change: Resistance to change is natural in any organization. Failing to address concerns, communicate benefits effectively, and involve employees in the process can stall progress and breed skepticism. Change Management is just as important as the Lean tools you’re implementing.

- Insufficient Training and Skills Development: Lean Six Sigma relies on trained professionals who understand the methodologies and tools. Inadequate training can lead to improper application of techniques and missed improvement opportunities. Investing in Lean training and coaching will accelerate your success and ensure the long-term sustainability of your process improvements.

- Failure to Measure and Celebrate Success: Measurement is essential for tracking progress and demonstrating ROI. Failing to measure outcomes and celebrate successes can demotivate teams and obscure the value of Lean Six Sigma investments.

Avoiding these common mistakes is essential for maximizing the benefits of Lean Six Sigma in manufacturing. By focusing on strategic planning, stakeholder engagement, data-driven decision-making, and fostering a culture of continuous improvement, companies can achieve sustainable operational excellence and competitive advantage.

Are you ready to embark on a Lean Six Sigma journey tailored to your manufacturing operations? Let’s connect and discuss how Engineering Possibilities can support your organization in achieving lasting improvements and business success.

Recent Comments